Technologies

Technologies

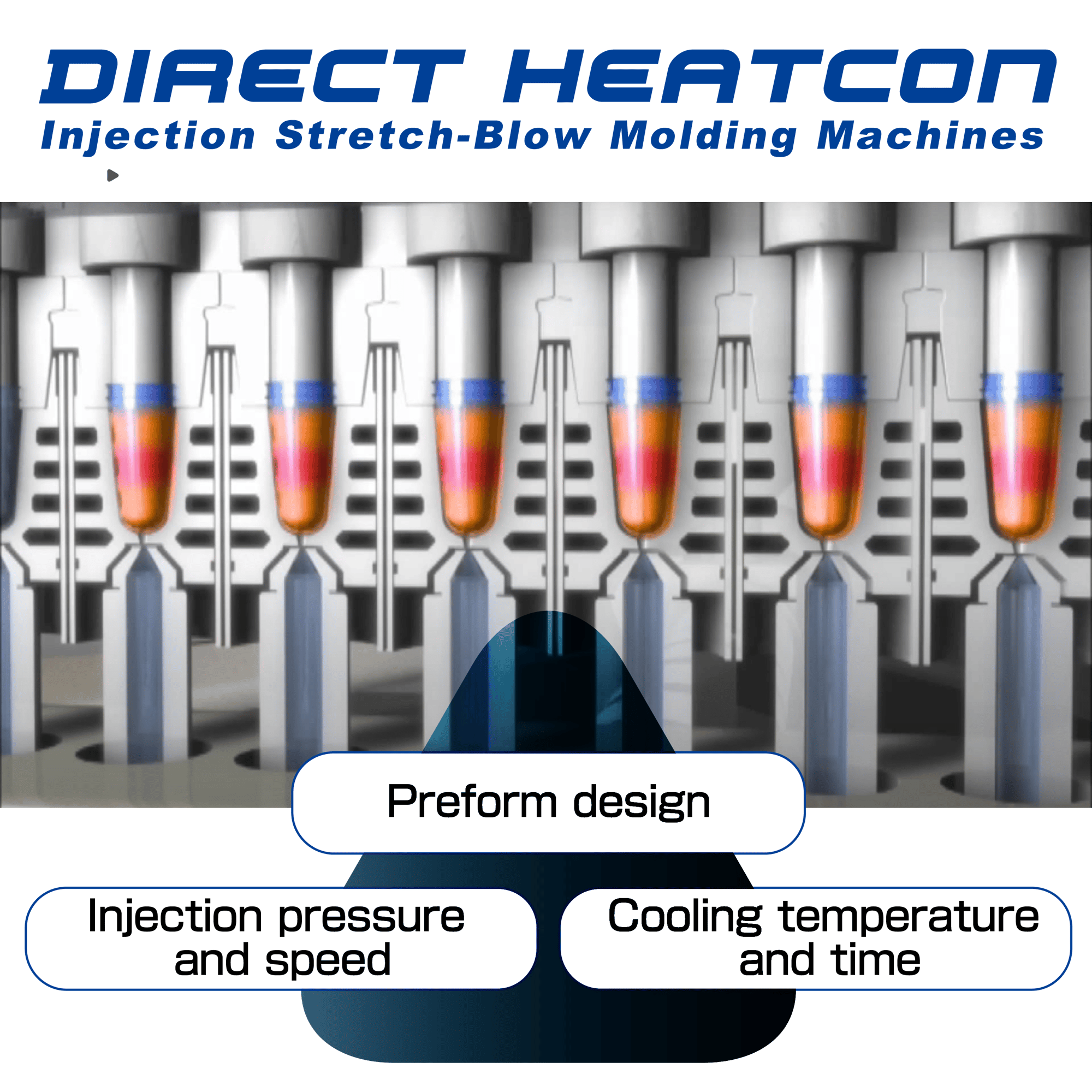

Direct Heatcon, Aoki’s key technology

Biaxial stretch-blow container molding technology dramatically improves the characteristics of plastics, and this has made it an essential part of our modern lives. Direct Heatcon is a proprietary injection stretch blow molding technology developed by Aoki that injection-molds and heat-conditions preforms at the same time, eliminating the need for reheating, and enabling raw material to be molded into finished containers using just three stations.

Aoki’s key technology

Single-stage, 3-station molding

The single-stage, 3-station system can control preform wall thickness, injection pressure, injection speed, and cooling time to create an accurate temperature profile by enabling quick stretch-blow molding while the preform still has its optimum temperature profile. With these machines, you will be able to mold containers that are true to your ideas.

Direct Heatcon technology allows molding from raw material to finished container using just three stations, without the need for a preform re-heating process. Going from raw material to finished container in as few as three processes drastically reduces molded bottle unit cost as well as enabling high volume production.

Aoki’s key technology

What is Direct Heatcon?

Direct Heatcon is an extremely efficient molding technology unique to Aoki that controls the temperature of the preform, an important aspect of plastic container molding, using only residual heat from the injection molding process.

Eliminating the need for a reheating step means that containers can be molded faster. Once the resin has reached the right temperature, container molding can be carried out after only a few shots of preform molding, thereby reducing the time required and enabling high-speed, energy-efficient container molding.

Using the residual heat from the preform molding process during stretch-blow molding totally eliminates preform re-heating expenses, and enables further savings in energy and space because preforms can be cooled in less time and chillers can be downsized. Direct Heatcon embodies Aoki's goal ever since its inception of molding containers with minimum expenditure of time and energy.

Aoki’s key technology

Direct Heatcon 3D CG movie

Watch this 3D CG movie to learn more about Direct Heatcon.

Technologies

Aoki’s molding method

Molding containers from material at highest speed worldwide

Aoki’s unique molding method

Aoki’s ever-evolving technology

Learn more about our development of new molding technologies, machine models, and more.

Technologies

Case studies

Inquiries about molding machines and container development

Please feel free to contact us if you are considering deploying molding machines or producing containers yourself.